Publicações

Interpreting rheology and electrical conductivity: It all boils down to which particle size

Cruz, RCD; Segadaes, AM; Mantas, PQ; Oberacker, R; Hoffmann, MJ

2020, JOURNAL OF COLLOID AND INTERFACE SCIENCE, 574, 97-109.

ISBN:

1095-7103

Processing and characterization of sinter-crystallized basalt glass-ceramics

Lima, LF; Mantas, PQ; Segadaes, AM; Cruz, RCD

2020, JOURNAL OF NON-CRYSTALLINE SOLIDS, 538.

ISBN:

1873-4812

Assessment of the use potential of iron ore tailings in the manufacture of ceramic tiles: From tailings-dams to brown porcelain

Fontes, WC; de Carvalho, JMF; Andrade, LCR; Segadaes, AM; Peixoto, RAF

2019, CONSTRUCTION AND BUILDING MATERIALS, 206, 111-121.

ISBN:

1879-0526

From dry pressing to plastic forming of ceramics: Assessing the workability window

Schiavo, LSA; Mantas, PQ; Segadaes, AM; Cruz, RCD

2018, CONSTRUCTION AND BUILDING MATERIALS, 189, 594-600.

Characterisation of refractory ceramic pressed body containing industrial waste

Frade, SB; Gomes, G; Correia, SL; Segadaes, AM

2018, MATERIALS SCIENCE FORUM, 912 MSF, 71-76.

Microstructure development in clays upon heat treatment: Kinetics and equilibrium

Santana, LNL; Gomes, J; Menezes, RR; Neves, GA; Lira, HL; Segadaes, AM

2017, APPLIED CLAY SCIENCE, 135, 325-332.

Reference material for temperature calibration of differential scanning calorimeters above 1400 A degrees C

Zorzi, JE; Segadaes, AM; Perottoni, CA

2017, JOURNAL OF THERMAL ANALYSIS AND CALORIMETRY, 128, 3, 1547-1554.

Castable systems designed with powders reclaimed from dismantled steel induction furnace refractory linings

Silva, AP; Segadaes, AM; Lopes, RA

2017, CERAMICS INTERNATIONAL, 43, 6, 5020-5031.

Double layer electrical conductivity as a stability criterion for concentrated colloidal suspensions

Cruz, RCD; Segadaes, AM; Oberacker, R; Hoffmann, MJ

2017, COLLOIDS AND SURFACES A-PHYSICOCHEMICAL AND ENGINEERING ASPECTS, 520, 9-16.

Assessment of the fluxing potential of igneous rocks in the traditional ceramics industry

Dias, FG; Segadaes, AM; Perottoni, CA; Cruz, RCD

2017, CERAMICS INTERNATIONAL, 43, 18, 16149-16158.

Property Optimisation of EPDM Rubber Composites Using Mathematical and Statistical Strategies

Correia, SL; Palaoro, D; Segadaes, AM

2017, ADVANCES IN MATERIALS SCIENCE AND ENGINEERING.

Granite waste and coffee husk ash synergistic effect on clay-based ceramics

Acchar, W; Avelino, KA; Segadaes, AM

2016, ADVANCES IN APPLIED CERAMICS, 135, 4, 236-242.

Low-valued raw materials challenge the common eligibility criteria for triaxial ceramics

Echeverrigaray, SG; Emiliano, JV; Segadaes, AM; Cruz, RCD

2016, CERAMICS INTERNATIONAL, 42, 9, 10671-10681.

Using mixture design of experiments to assess the environmental impact of clay-based structural ceramics containing foundry wastes

Coronado, M; Segadaes, AM; Andres, A

2015, JOURNAL OF HAZARDOUS MATERIALS, 299, 529-539.

Bactericidal potential of titania and silver nano powders deposited in porous ceramic substrates for low-power water purification reactors

Santos, IB; Acchar, W; Goncalves, JN; Segadaes, AM

2015, MATERIALS TODAY-PROCEEDINGS, 2, 1, 242-245.

Influence of fired clay brick waste additions on the durability of mortars

Schackow, A; Stringari, D; Senff, L; Correia, SL; Segadaes, AM

2015, CEMENT & CONCRETE COMPOSITES, 62, 82-89.

Combining mixture design of experiments with phase diagrams in the evaluation of structural ceramics containing foundry by-products

Coronado, M; Segadaes, AM; Andres, A

2014, APPLIED CLAY SCIENCE, 101, 390-400.

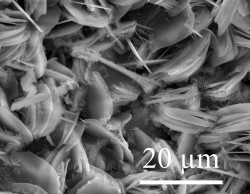

Mullite formation from bentonites containing kaolinite: Effect of composition and synthesis parameters

Santana, LNL; Gomes, J; Neves, GA; Lira, HL; Menezes, RR; Segadaes, AM

2014, APPLIED CLAY SCIENCE, 87, 28-33.

Incorporation of Fired Ceramic Waste into Binary and Ternary Earth-Binder(S) Mixtures for Compressed Blocks

Acchar, W; Silva, JB; Silva, VM; Gois, LC; Segadaes, AM

2014, BRAZILIAN CERAMIC CONFERENCE 57, 798-799, 498-+.

ISBN:

978-3-03835-114-6

Untreated coffee husk ashes used as flux in ceramic tiles

Acchar, W; Dultra, EJV; Segadaes, AM

2013, APPLIED CLAY SCIENCE, 75-76, 141-147.

Increased added value reuse of construction waste in clay based building ceramics

Acchar, W; Silva, JE; Segadaes, AM

2013, ADVANCES IN APPLIED CERAMICS, 112, 8, 487-493.

Thermomechanical evaluation of self-flowing refractory castables with and without the addition of aluminate cement

Pinto, DG; Silva, AP; Segadaes, AM; Devezas, TC

2012, CERAMICS INTERNATIONAL, 38, 4, 3483-3488.

Combining mineral and clay-based wastes to produce porcelain-like ceramics: An exploratory study

Junkes, JA; Prates, PB; Hotza, D; Segadaes, AM

2012, APPLIED CLAY SCIENCE, 69, 50-57.

MgAl2O4 spinel synthesis by combustion and detonation reactions: A thermochemical evaluation

Duraes, L; Matias, T; Segadaes, AM; Campos, J; Portugal, A

2012, JOURNAL OF THE EUROPEAN CERAMIC SOCIETY, 32, 12, 3161-3170.

Effect of particle size distribution and calcium aluminate cement on the rheological behaviour of all-alumina refractory castables

Silva, AP; Segadaes, AM; Pinto, DG; Oliveira, LA; Devezas, TC

2012, POWDER TECHNOLOGY, 226, 107-113.

Influence of Carbon Black, Calcium Carbonate and Dioctyl Phthalate Compositions on the NBR Vulcanized Rubber Properties Through Experiments Design

Correia, SL; Palaoro, D; Mautone, A; Segadaes, AM

2012, MACROMOLECULAR SYMPOSIA, 319, 1, 161-166.

Assessment of reuse potential of high alumina industrial waste as devitrification aid in common alumina-lime-silica glasses

Mello-Castanho, SRH; Ferreira, MC; Acchar, W; Segadaes, AM

2011, ADVANCES IN APPLIED CERAMICS, 110, 7, 426-432.

Mechanical properties of a lithium glass-ceramic matrix (LZSA) reinforced with TiC or (W,Ti)C particles: A preliminary study

Acchar, W; Segadaes, AM

2010, COMPOSITE STRUCTURES, 92, 3, 707-711.

Factorial design used to model the compressive strength of mortars containing recycled rubber

Correia, SL; Partala, T; Loch, FC; Segadaes, AM

2010, COMPOSITE STRUCTURES, 92, 9, 2047-2051.

Designing particle sizing and packing for flowability and sintered mechanical strength

Silva, AP; Pinto, DG; Segadaes, AM; Devezas, TC

2010, JOURNAL OF THE EUROPEAN CERAMIC SOCIETY, 30, 14, 2955-2962.

Effect of the incorporation of a spent catalyst reject from the petroleum industry in clay products

Acchar, W; Rulff, BM; Segadaes, AM

2009, APPLIED CLAY SCIENCE, 42, 3-4, 657-660.

Properties of sintered alumina reinforced with niobium carbide

Acchar, W; Segadaes, AM

2009, INTERNATIONAL JOURNAL OF REFRACTORY METALS & HARD MATERIALS, 27, 2, 427-430.

Effect of quartz sand replacement by agate rejects in triaxial porcelain

Correia, SL; Dienstmann, G; Fogueras, MV; Segadaes, AM

2009, JOURNAL OF HAZARDOUS MATERIALS, 163, 1, 315-322.

Assessment of the recycling potential of fresh concrete waste using a factorial design of experiments

Correia, SL; Souza, FL; Dienstmann, G; Segadaes, AM

2009, WASTE MANAGEMENT, 29, 11, 2886-2891.

Predicting porosity content in triaxial porcelain bodies as a function of raw materials contents

Correia, SL; Hotza, D; Segadaes, AM

2008, JOURNAL OF MATERIALS SCIENCE, 43, 2, 696-701.

Al-27 and Si-29 NMR and XRD characterisation of clinkers: standard phases and new waste based formulations

Raupp-Pereira, F; Segadaes, AM; Silva, AS; Rocha, J; Labrincha, JA

2008, ADVANCES IN APPLIED CERAMICS, 107, 1, 37-45.

Aluminum anodizing sludge used to fabricate engobes, glazes and frits

Sartor, MN; Correia, SL; Hotza, D; Segadaes, AM; Labrincha, JA; de Oliveira, APN

2008, AMERICAN CERAMIC SOCIETY BULLETIN, 87, 5, 9201-U3.

Setting behaviour of waste-based cements estimated by impedance spectroscopy and temperature measurements

Raupp-Pereira, F; Ribeiro, MJ; Segadaes, AM; Labrincha, JA

2007, BOLETIN DE LA SOCIEDAD ESPANOLA DE CERAMICA Y VIDRIO, 46, 2, 91-96.

Potable water filtration sludge: Use as set retarder in one-coat plastering mortars

Raupp-Pereira, F; Silva, L; Segadaes, AM; Hotza, D; Labrincha, JA

2007, CONSTRUCTION AND BUILDING MATERIALS, 21, 3, 646-653.

Extrusion and property characterisation of waste-based ceramic formulations

Raupp-Pereira, F; Ribeiro, MJ; Segadaes, AM; Labrincha, JA

2007, JOURNAL OF THE EUROPEAN CERAMIC SOCIETY, 27, 5, 2333-2340.

Effects of potable water filtration sludge on the rheological behaviour of one-coat plastering mortars

Raupp-Pereira, F; Silva, L; Segadaes, AM; Paiva, H; Labrincha, JA

2007, JOURNAL OF MATERIALS PROCESSING TECHNOLOGY, 190, 1-3, 12-17.

Ceramic formulations prepared with industrial wastes and natural sub-products

Raupp-Pereira, F; Hotza, D; Segadaes, AM; Labrincha, JA

2006, CERAMICS INTERNATIONAL, 32, 2, 173-179.

Using ornamental stone cutting rejects as raw materials for red clay ceramic products: Properties and microstructure development

Acchar, W; Vieira, FA; Segadaes, AM

2006, MATERIALS SCIENCE AND ENGINEERING A-STRUCTURAL MATERIALS PROPERTIES MICROSTRUCTURE AND PROCESSING, 435, 606-610.

Properties of triaxial porcelain bodies: Interpretation of statistical modeling

Correia, SL; Oliveira, APN; Hotza, D; Segadaes, AM

2006, JOURNAL OF THE AMERICAN CERAMIC SOCIETY, 89, 11, 3356-3365.

Use of phase diagrams to guide ceramic production from wastes

Segadaes, AM

2006, ADVANCES IN APPLIED CERAMICS, 105, 1, 46-54.

Statistical modelling of the particle size composition of an alumina matrix for no-cement self-flowing refractory castables

Silva, A; Segadaes, A; Devezas, T

2006, ADVANCED MATERIALS FORUM III, PTS 1 AND 2, 514-516, 604-608.

Optimising mechanical strength and bulk density of dry ceramic bodies through mixture design

Correia, SL; Hotza, D; Segadaes, AM

2005, BOLETIN DE LA SOCIEDAD ESPANOLA DE CERAMICA Y VIDRIO, 44, 1, 53-58.

Using marble and granite rejects to enhance the processing of clay products

Segadaes, AM; Carvalho, MA; Acchar, W

2005, APPLIED CLAY SCIENCE, 30, 1, 42-52.

Electrical conductivity and stability of concentrated aqueous alumina suspensions

Cruz, RCD; Reinshagen, J; Oberacker, R; Segadaes, AM; Hoffmann, MJ

2005, JOURNAL OF COLLOID AND INTERFACE SCIENCE, 286, 2, 579-588.

Effect of tungsten carbide additions on the microstructure and properties of hot-pressed alumina

Acchar, W; Cairos, CA; Segadaes, AM

2005, MATERIALS SCIENCE AND ENGINEERING A-STRUCTURAL MATERIALS PROPERTIES MICROSTRUCTURE AND PROCESSING, 406, 1-2, 74-77.

Using experiments design to model linear firing shrinkage of triaxial ceramic bodies

Correia, SL; Curto, KAS; Hotza, D; Segadaes, AM

2005, ADVANCED POWDER TECHNOLOGY IV, 498-499, 430-435.

ISBN:

0-87849-984-9

Clays from southern Brazil: physical, chemical and mineralogical characterization

Correia, SL; Curto, KAS; Hotza, D; Segadaes, AM

2005, ADVANCED POWDER TECHNOLOGY IV, 498-499, 447-452.

ISBN:

0-87849-984-9

Catalyst preparation by combustion synthesis for electrochemical hydrocarbon devices

Chinarro, E; Segadaes, AM; Jurado, JR

2004, JOURNAL OF SOLID STATE ELECTROCHEMISTRY, 8, 9, 606-610.

Simultaneous optimization of linear firing shrinkage and water absorption of triaxial ceramic bodies using experiments design

Correia, SL; Hotza, D; Segadaes, AM

2004, CERAMICS INTERNATIONAL, 30, 6, 917-922.

Using statistical techniques to model the flexural strength of dried triaxial ceramic bodies

Correia, SL; Curto, KAS; Hotza, D; Segadaes, AM

2004, JOURNAL OF THE EUROPEAN CERAMIC SOCIETY, 24, 9, 2813-2818.

Moisture expansion: Activation energy versus firing temperature

Carvalho, MA; Segadaes, AM

2004, EURO CERAMICS VIII, PTS 1-3, 264-268, 1581-1584.

ISBN:

0-87849-946-6

Refractory formulations made of different wastes and natural sub-products

Pereira, FR; Nunes, AF; Segadaes, AM; Labrincha, JA

2004, EURO CERAMICS VIII, PTS 1-3, 264-268, 1743-1746.

ISBN:

0-87849-946-6

Rheological behaviour of clay-based slurries: effect of the preparation methods - (Lab-scale or typical industrial procedures)

Pereira, FR; Oliveira, AP; De Noni, A; Hotza, D; Segadaes, AM; Labrincha, JA

2003, INDUSTRIAL CERAMICS, 23, 2, 87-92.

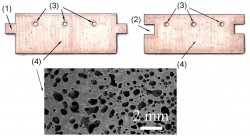

Microstructure, permeability and mechanical behaviour of ceramic foams

Lopes, RA; Segadaes, AM

1996, MATERIALS SCIENCE AND ENGINEERING A-STRUCTURAL MATERIALS PROPERTIES MICROSTRUCTURE AND PROCESSING, 209, 1-2, 149-155.

Phase equilibrium relationships in the system Al2O3-TiO2-MnO, relevant to the low-temperature sintering of alumina

Moreira, MC; Segadaes, AM

1996, JOURNAL OF THE EUROPEAN CERAMIC SOCIETY, 16, 10, 1089-1098.

Combustion synthesis of calcium aluminates

Fumo, DA; Morelli, MR; Segadaes, AM

1996, MATERIALS RESEARCH BULLETIN, 31, 10, 1243-1255.

PROCESSING AND CHARACTERIZATION OF THIN-FILMS OF THE 2-LAYER SUPERCONDUCTING PHASE IN THE BI-SR-CA-CU-O SYSTEM - EVIDENCE FOR SOLID-SOLUTION

GOLDEN, SJ; BLOOMER, TE; LANGE, FF; SEGADAES, AM; VAIDYA, KJ; CHEETHAM, AK

1991, JOURNAL OF THE AMERICAN CERAMIC SOCIETY, 74, 1, 123-129.

COMPATIBILITY RELATIONSHIPS IN THE SYSTEM CAO.SIO2-FE2O3-FEO

CANHA, RH; SEGADAES, AM

1986, JOURNAL DE PHYSIQUE, 47, C-1, 461-466.

Refractários

Ana M. Segadães

1997, Aveiro, Universidade de Aveiro, Fundação J. J. Magalhães.

ISBN:

972-8283-21-8

Anais de MATERIAIS'95 - VII Encontro Nacional da Sociedade Portuguesa de Materiais

Ana M. Segadães

1995, Aveiro, Fundação João Jacinto de Magalhães, Universidade de Aveiro.

Diagramas de Fases — Teoria e Aplicação em Cerâmica

Ana M. Segadães

1987, São Paulo, Edgard Blücher, Lda.

A Non-Linear Programming Approach for Formulation of Three-Component Ceramics as a Function of Physical and Mechanical Properties

In Edgar Lara-Curzio (Eds.), Mechanical Properties and Performance of Engineering Ceramics and Composites: Ceramic Engineering and Science Proceedings

Correia SL, Gomes CM, Hotza D, Segadães AM

2008, 26 (2).

ISBN:

9781574982329

Refractories in Portugal: Industry, Education and Research

In Carmen Baud’n (Eds.), Refractarios Monol’ticos

Ana M. Segad‹es

1999, 55-64, Madrid, Sociedad Espa–ola de Cer‡mica y Vidrio.

ISBN:

84-8198-306-3

Reaction-Sintered MulliteÐZirconia Composites: Mechanism and Properties

In S. Meriani, C. Palmonari (Eds.), Advances in Zirconia Science and Technology

J.V. Emiliano, A.M. Segad‹es

1989, 51-66, Elsevier Sci. Pub. Ltd..

ISBN:

978-94-010-7005-8 (print), 978-94-009-1139-0 (on-line)

Patentes

Bloco nanocelular para construção de alvenarias

Products InternacionalNacional

Segadães, Ana; Morelli, Márcio; Zurba, Nadia

A presente invenção refere-se a um bloco cerâmico muito poroso (compósito celular) para construção de alvenarias, à base de cimento de fosfato de magnésio, com uma resistência mecânica raramente encontrada em produtos com porosidad...Método de preparação de artefactos cerâmicos porosos

Processes InternacionalNacional

Segadães, Ana; Morelli, Márcio; Zurba, Nadia

A presente invenção refere-se ao método de preparação, rápido e à temperatura ambiente, de um novo material cerâmico muito poroso, que associa a presa rápida dos cimentos de fosfato de magnésio à libertaç&am...Pavimento hidroactivo fertilizante do ciclo geobioquímico da fotossíntese

Products InternacionalNacional

Segadães, Ana; Morelli, Márcio; Zurba, Nadia

A presente invenção refere-se a ladrilhos de pavimentação auto-travada antiderrapante, assentados sem recurso a argamassa colante, muito porosos, à base de cimento de fosfato de magnésio, obtidos à temperatura ambiente por vazamento em molde.Os ladr...